Laser Cutting Documentation!

- shaira214

- Oct 22, 2022

- 2 min read

Updated: Nov 5, 2022

What is laser cutting?

Laser cutters create patterns and designs by cutting into materials. A powerful laser beam is the source that melts, burns, or vaporizes the material.

Essentially, laser cutting is a fabrication process that uses a thin, focused, laser beam to cut and etch materials into custom designs, patterns, and shapes as specified by a designer. This non-contact, thermal-based fabrication process is ideal for several materials, including wood, glass, paper, metal, plastic, and gemstone. It’s also capable of producing intricate parts without needing a custom-designed tool.

You might ask yourself, how does laser cutting work?

In a CO2 laser cutter machine, the laser beam is created in a tube filled with CO2 gas. Next, with the help of mirrors and lenses, the laser beam is directed to the laser head and focused on the material surface.

Electronically controlled motors move the laser head to cut or engrave the desired shape into the material of the workpiece. The assist gas is from the compressor. Blowing compressed air at the area being laser cut helps prevent flare ups and keeps things clean by directing vaporized material downward and away from the cut, and away from the machine’s lenses and mirrors.

In this page, I will describe:

The 4 important hazards associated with the operation of laser cutting machines and their respective safety control measures (administrative/engineering control).

2. The materials that can be cut and can’t be cut using a laser cutting machine.

3. The steps including pictures on the operation of UNIVERSAL laser cutter, that consist of:

3a. Starting the compressor, turning on the laser cutter machine and fume extractor.

3b. Importing a .DXF file to CorelDraw and modify the lines/fill for cutting and engraving.

3c. Sending the CorelDraw drawing to laser cutter software and setting the laser cutter power, speed, PPI in the software.

4. Starting the job on the laser cutter machine.

5. DOs and DONTs when there’s flame/fire on the material being cut.

6. My Learning reflection on laser cutter activities.

The 4 important hazards associated with the operation of laser cutting machines and their respective safety control measures:

Hazards | Safety Control Measures |

Risk of Burns | do not touch hot surfaces (administrative) |

Laser Radiation | Close the machine cover before the operation (administrative) |

Blaze Hazard | Do not touch sharp blades keep hands clear do not remove chips by hand (administrative) |

Dust Fumes Inhalation | Switch on the exhaust filtration system. |

Materials that can be cut/engraved using laser cutting machine in FabLab:

Material | Photo of the material |

1.paper/white card |  |

2. Cardboard |  |

3. Balsa Wood |  |

4. Acrylic |  |

5. Plywood |  |

Materials that can’t be cut/engraved using laser cutting machine in Fablab:

Material | Photo of material |

1.PVC |  |

2. Metal |  |

3. Foam |  |

4. Rubber |  |

Below are the steps on the operation of UNIVERSAL laser cutter machine in FabLab:

Steps and Descriptions | Photos to support the description |

|  |

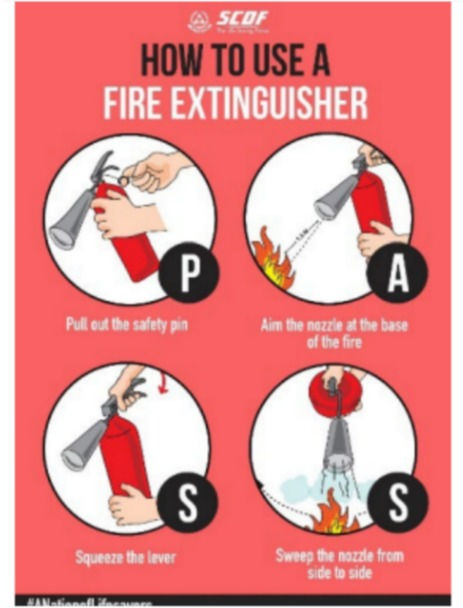

2. Locate the fire extinguisher |  |

Importing a .DXF file to CorelDraw and modify the lines/fill for cutting and engraving:

Steps | Pictures |

|  |

2. Click on outside the box |  |

3. Press the lock icon, and scale the design accordingly. |  |

4. If you are going to be cutting, choose the option “hairline”. |  |

5. Check if the dimensions of the drawings are enough to fit into the material, by using the scale in the machine. |  |

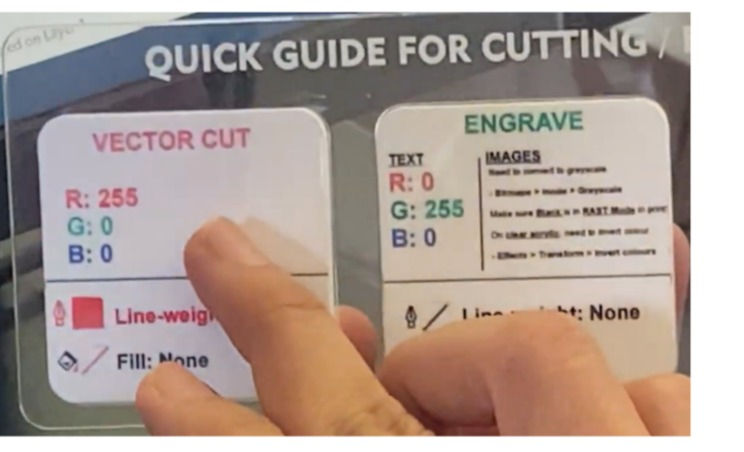

6. Change the color of the drawings. (Use vector cut from the Quick Guide) |  |

7. Double click the black box. |  |

8. Change the color from black to red, and click “ok”. |  |

Sending the CorelDraw drawing to laser cutter software and setting the laser cutter power, speed, PPI in the software:

|  |

2. Go to Settings. |  |

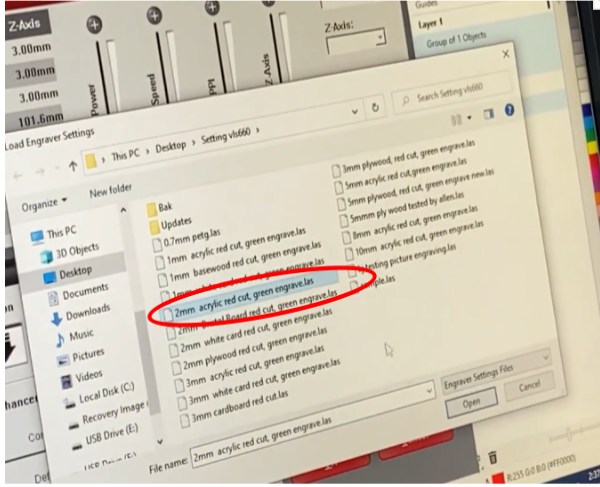

3. Press “Load”. |  |

4. Choose the file according to the material and thickness of the material being used. |  |

5. If the color red or green is being used, make sure the setting is set to “Rast/Vec”. *If the setting is set to Black, “Skip”, nothing will be cut. |  |

6. Press “Apply” and “Ok” |  |

7. Click on “Print” |  |

8. Click on UCP, as known as , “Universal Control Panel”. |  |

Starting the job on the laser cutter machine:

Steps | Pictures |

|  |

2. Turn on the grey “play button” by manually turning on the red “switch” button to activate the laser cutting machine. |  |

3. Take off the paper surface at the top of the sheet, as it would cause burning, and leave the paper surface at the bottom layer of the sheet to protect the plastic sheet. |  |

4. Type in the values of the coordinates you want the laser pointed to be located on, on the sheet of plastic. [coordinates of (0.51,0.51) is better than (0,0) as sometimes the material may not be straight, and it will also save material] |  |

5. Click on the “estimate” view to see how long the laser cutting process would take. |  |

6. Close the laser cutting machine cover |  |

7. Press on any of the 2 green buttons to start the laser cutting process. |  |

DOs and DONTs when there’s flame/fire on the material being cut:

Do's ✅ | Dont's ❎ | Pictures to support |

If there is an alarm sound while working, immediately stop work and wait for instructions from Staff-in-charge. | Do not close the laser cutter machine cover if there is a flame on the material. | |

If small fire occur, attempt to extinguish by blowing it or remove material from laser cutter | Do not ignore any flames, no matter how small or big it is. | |

If the fire is unable to blow off, a. remove material from the laser cutter b. place it on the floor and step on it to put out the fire | Do not try to use the machines in FabLab, if you are unsure on how to use it. Always consult with the staff-in-charge, or ask for help from people around you. | |

If the fire is uncontrollable, go to the closest fire extinguisher and put it out. Get people’s attention by shouting for help. | |  |

Learning reflection:

For the laser cutting competency test, we were required to create a set of SOP for the laser cutter with only some online learning materials and videos provided to us on Brightspace. We were never really briefed properly, or even entered FabLab before, causing us to be stressed and worried about the test. Some of us even created SOPs of almost 20 pages, when the recommended was 3.

Fortunately, the laser cutting certification test was not as challenging as I had expected it to be. I feel that everyone was rather clear on what they had to do, and the tasks to complete to pass the test.

Comments